Welcome to the Pulisonic Digital Ultrasonic Generator

Hotline:86-0757-29363805

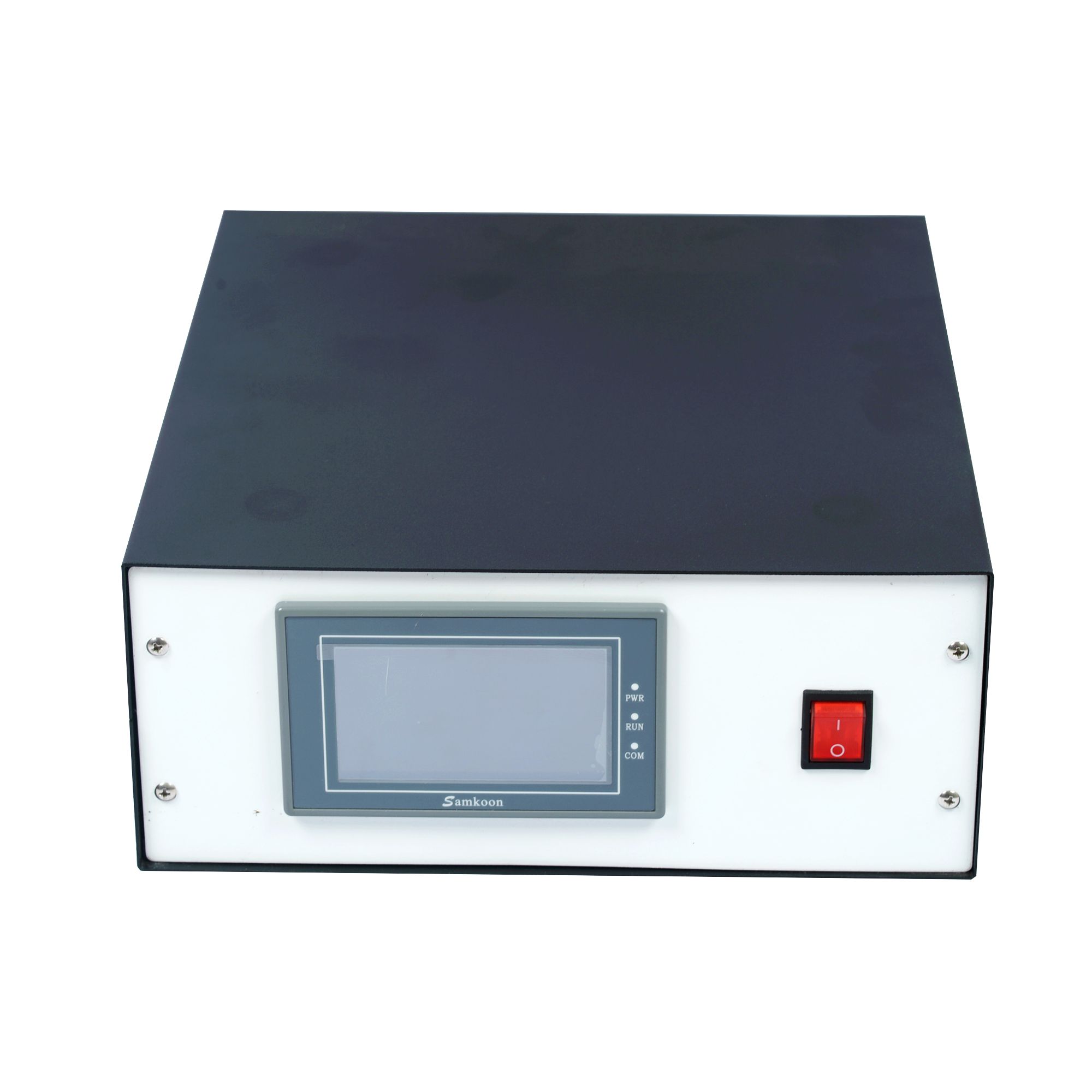

4200W/2000W Ultrasonic Wire Welding Generator Metal Wire Harness Welding

Category:Industry dynamics

Application scope of ultrasonic welding generator

Automotive interior parts, electronics, stationery, transportation equipment, food, chemical products, household appliances, toys, non-woven fabrics, non-standard automation. Folder positioning, solder joint, riveting, cutting, engraving, plastic hardware, system integration and supporting.

Ultrasonic welding generator uses high-frequency vibration wave to transmit to two object surfaces to be welded. Under pressure, the two object surfaces rub against each other to form fusion between molecular layers. Ultrasonic welding converts 50 / 60 Hz current into 15, 20, 30 or 40KHz electric energy through ultrasonic generator, and the converted high-frequency electric energy is converted into mechanical motion of the same frequency through transducer, Then, the mechanical motion is transmitted to the welding head through a set of luffing rod device that can change the amplitude. The welding head transmits the received vibration energy to the joint of the workpiece to be welded. In this area, the vibration energy is converted into heat energy by friction to melt the plastic. Ultrasonic wave can be used not only to weld hard thermoplastic plastics, but also to process fabrics and films. When ultrasonic wave acts on the contact surface of thermoplastic plastics, it will produce tens of thousands of high-frequency vibration per second. This high-frequency vibration with a certain amplitude will transmit ultrasonic energy to the welding area through the upper weldment. Due to the large acoustic resistance at the interface between the two welding areas, local high temperature will be generated, but, The ultrasonic welding machine in the prior art is prone to interval during work, can not carry out continuous work, and there is no special transportation equipment, resulting in slow work efficiency. At the same time, it needs to spend manpower for operation and supervision. Therefore, we propose a continuous welding ultrasonic welding machine.

The ultrasonic signal generator is composed of an ultrasonic power amplifier module which can convert 50 / 60Hz power frequency AC into ultrasonic frequency for the work of the transducer and a control module with "system protection monitoring" and "automatic tuning" functions. The control module can cut off the ultrasonic energy when the ultrasonic welding fails, so as to provide high safety and reliability for the generator and even the whole set of welding equipment.

The built-in automatic constant amplitude system can automatically compensate for different air pressure changes and voltage fluctuations, and can steplessly adjust the ultrasonic amplitude from 50% - 100%, so as to meet the requirements of different welding workpieces.

Using IGBT for power amplification, the reaction is fast, which is more than 100 times faster than the traditional silicon power tube, so the protection function is better.

Model | Power | Frequency |

PLS-HJDY-300W | 300W | 28KHZ,30KHZ,35KHZ,40KHZ |

PLS-HJDY-500W | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

PLS-HJDY-800W | 800W | 28KHZ,30KHZ,35KHZ,40KHZ |

PLS-HJDY-1000W | 1000W | 15KHZ,20KHZ,28KHZ |

PLS-HJDY-1200W | 1200W | 15KHZ,20KHZ,28KHZ |

PLS-HJDY-1500W | 1500W | 15KHZ,20KHZ |

PLS-HJDY-2000W | 2000W | 15KHZ,20KHZ |

PLS-HJDY-2600W | 2600W | 15KHZ,20KHZ |

PLS-HJDY-3200W | 3200W | 15KHZ |

PLS-HJDY-4200W | 4200W | 15KHZ |

4200W/2000W Ultrasonic Wire Welding Generator Metal Wire Harness Welding