Welcome to the Pulisonic Digital Ultrasonic Generator

Hotline:86-0757-29363805

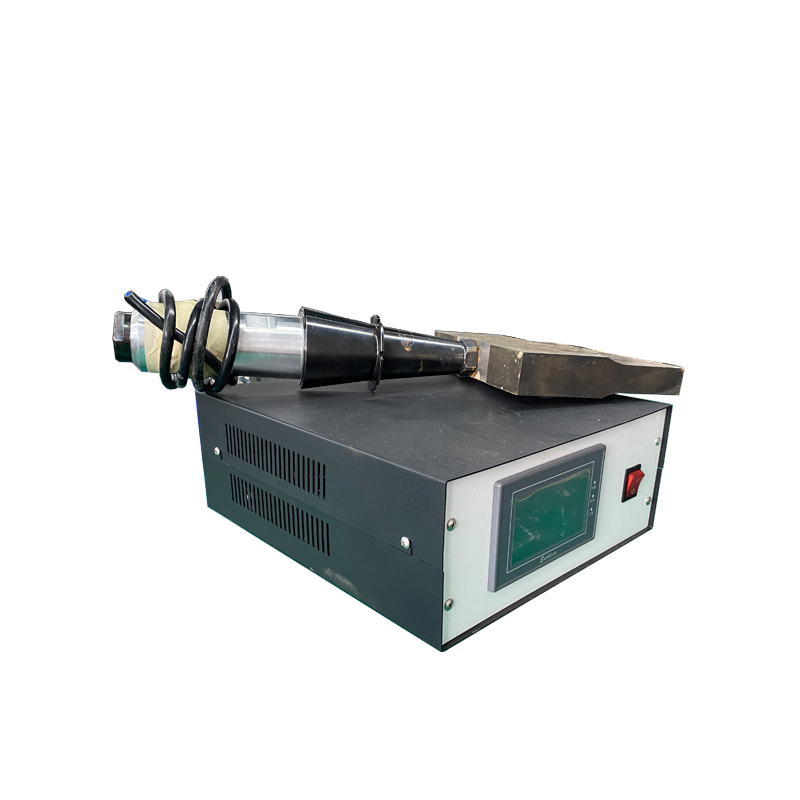

28khz 800W Single Frequency Ultrasonic Plastic Welding Generator For Abs Pp Pe Plastic Material Welding

Category:Industry dynamics

The advantages of ultrasonic wire harness welding are: no flux and shielding gas are required. The welding contact is an alloy layer fused into one, with stable chemical properties and good conductivity. The resistance system is basically consistent with the original coefficient of the material; No spatter, bright solder joints, no exposed copper coating, and no cracking of terminals.

The wire harness ultrasonic metal welding power generator is applied to the wire harness welding processing of wires, cables and connectors in automobile, motorcycle, electric vehicle, motor, electronics, electrical appliances, batteries, computers, communication equipment, instruments and meters and other industries.

Model | Power | Frequency |

PLS-HJDY-300W | 300W | 28KHZ,30KHZ,35KHZ,40KHZ |

PLS-HJDY-500W | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

PLS-HJDY-800W | 800W | 28KHZ,30KHZ,35KHZ,40KHZ |

PLS-HJDY-1000W | 1000W | 15KHZ,20KHZ,28KHZ |

PLS-HJDY-1200W | 1200W | 15KHZ,20KHZ,28KHZ |

PLS-HJDY-1500W | 1500W | 15KHZ,20KHZ |

PLS-HJDY-2000W | 2000W | 15KHZ,20KHZ |

PLS-HJDY-2600W | 2600W | 15KHZ,20KHZ |

PLS-HJDY-3200W | 3200W | 15KHZ |

PLS-HJDY-4200W | 4200W | 15KHZ |

28khz 800W Single Frequency Ultrasonic Plastic Welding Generator For Abs Pp Pe Plastic Material Welding